- Home

- Services

- Products

- Industries

- About us

- +44 (0) 1733 666701

- info@enertherm-engineering.com

- Mon - Fri: 8:30 - 17:00

An industrial dehydrator is a machine that is used to remove moisture from food or other materials on a large scale. This process, known as dehydration, can help to preserve the shelf life of the material and make it easier to transport or store. Industrial dehydrators can be used to dry a wide variety of materials, including fruits, vegetables, meats, and even industrial products such as wood chips or ceramics. They can come in different sizes, designs and can operate with different technology such as hot air, vacuum, microwave, etc. depending on the type of food or materials being dehydrated.

Our dehydrator design offers a number of benefits to users, such as:

High efficiency - Designed to remove moisture quickly and efficiently, reducing the time and energy needed for the dehydration process.

Customizable - Tailored to specific needs and requirements, such as size, features, and type of products to dehydrate.

Our industrial dehydrator design is a versatile, efficient and safe solution for businesses looking to extend the shelf life of food and other materials, reduce costs, increase efficiency and improve product quality. It is designed to remove moisture quickly and efficiently, customizable, user-friendly, durable, energy-efficient and cost-effective. It can be used in a wide range of industries and for a variety of materials and it offers cost savings on transportation and storage, improved product quality and safety, and reduced environmental impact.

Designing an industrial dehydrator typically involves several steps:

Needs assessment: The first step is to determine the specific needs of the business. This includes assessing the types of products that will be dehydrated, the quantity of products that will be processed, and any special requirements or constraints.

Conceptual design: Once the needs are understood, the conceptual design is created. This involves developing a general layout of the dehydrator and determining the key components that will be needed.

Detailed design: The conceptual design is then refined and developed into a detailed design. This includes specifying the exact dimensions and materials of the dehydrator and selecting the appropriate drying technology.

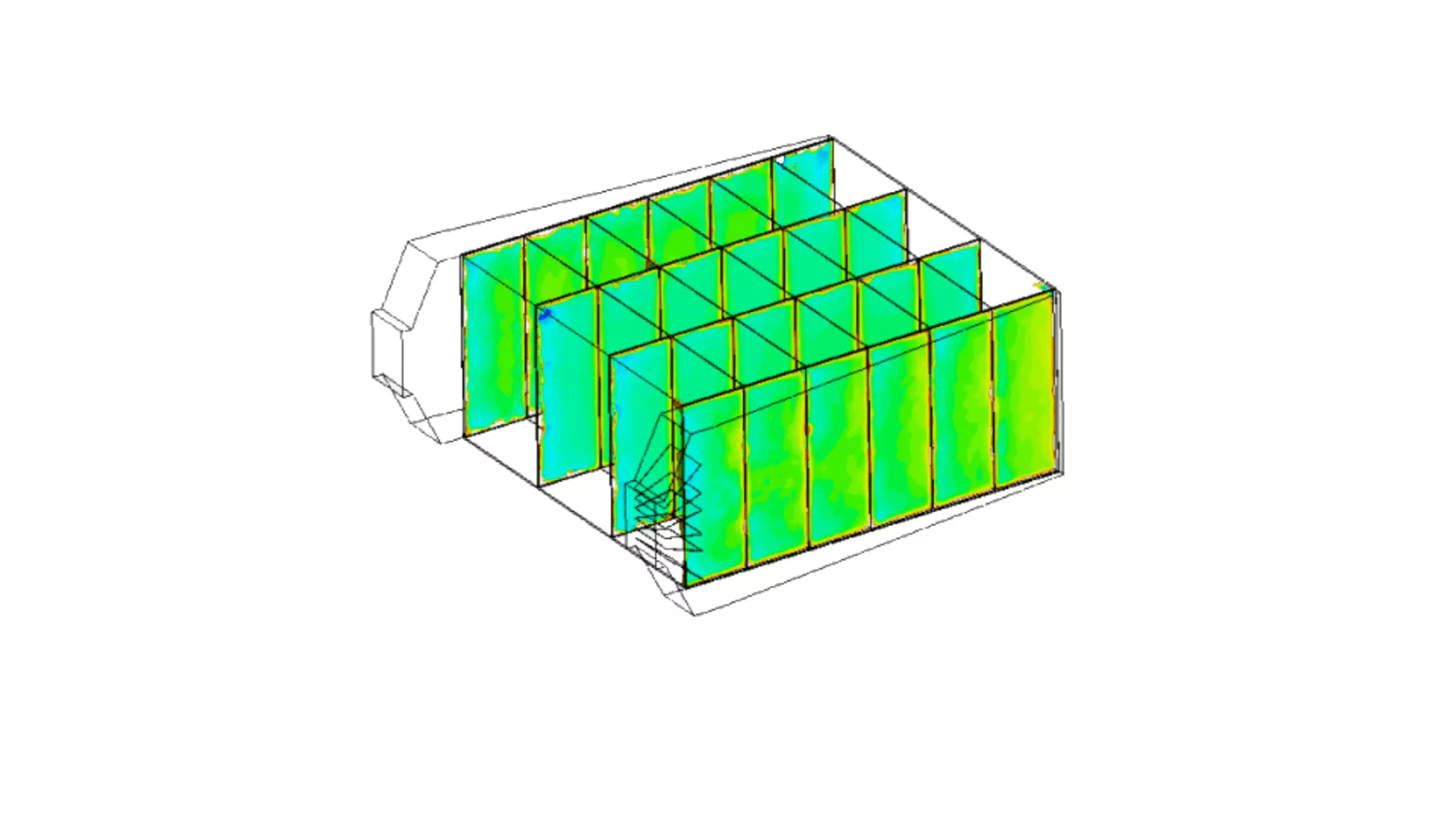

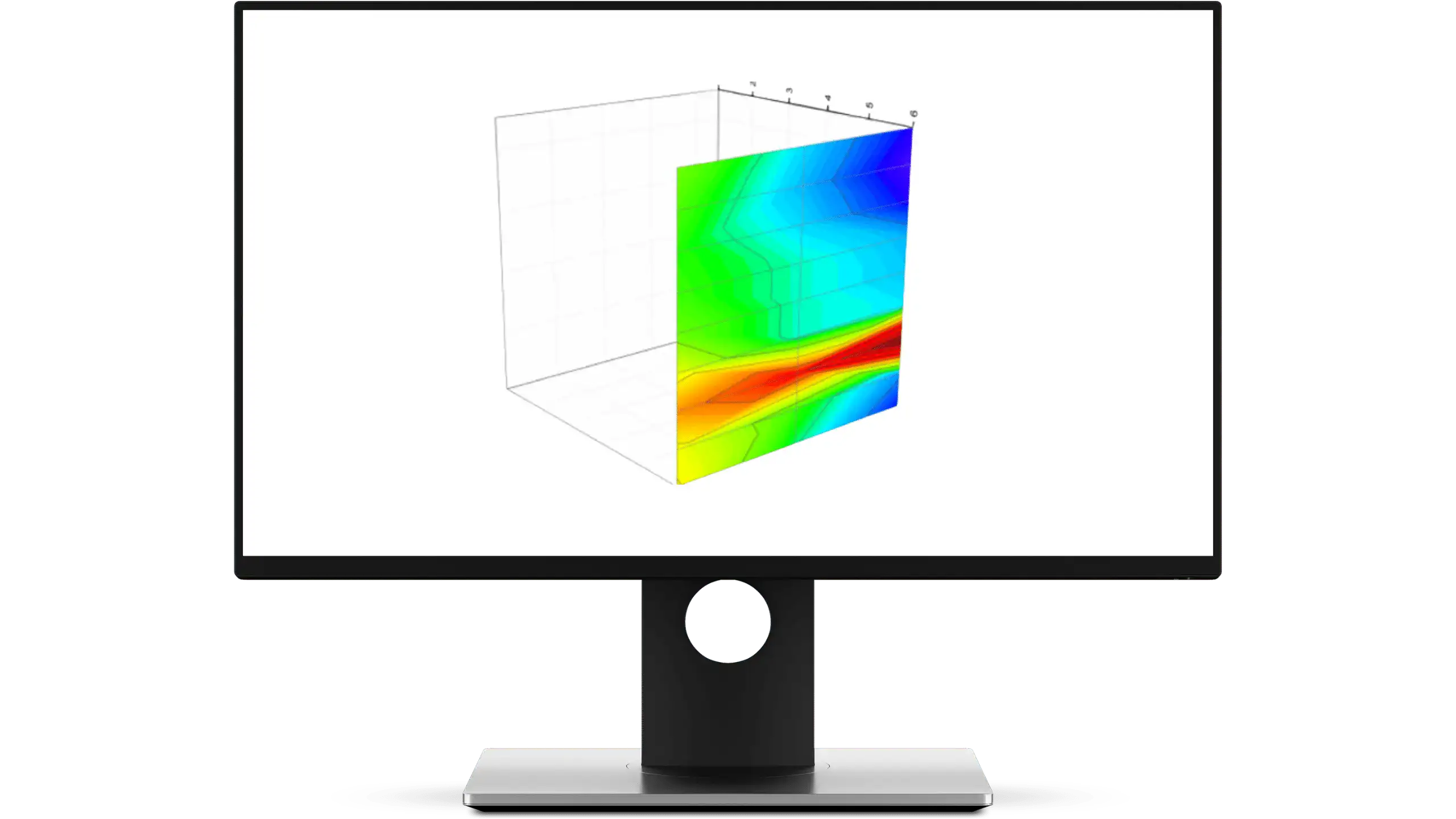

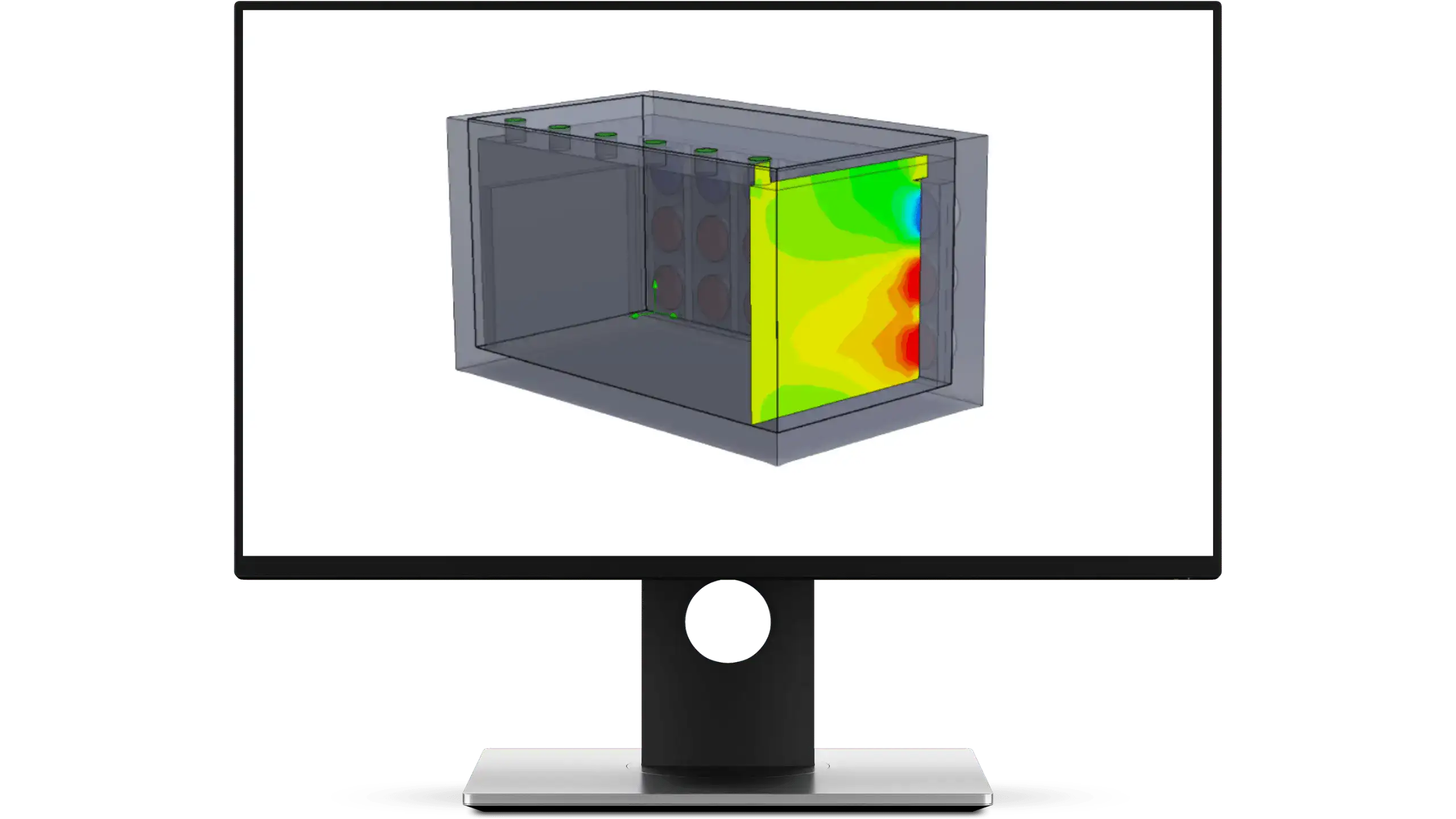

Simulation and testing: The detailed design is then simulated and tested to ensure that it will perform as expected. This includes testing the drying process and evaluating the energy efficiency of the dehydrator.

Final design: After simulation and testing, the final design is created. This includes the complete set of technical drawings, schematics and bill of materials. Once the design is finalized, we will invite you to conduct a Virtual Factory Acceptance Test (VFAT). This will allow you to take a virtual tour of the newly designed dehydrator installation using virtual reality technology. You will have the opportunity to review the CAD drawing in detail and identify any adjustments or changes you would like to see made before installation begins. By doing this, we can avoid unnecessary expenses and modifications after installation.

Fabrication and assembly: The final design is then used to fabricate and assemble the dehydrator. This involves cutting, bending and welding the various components together to create the final product.

Installation and commissioning: The dehydrator is then installed and commissioned at the customer's facility, and any necessary adjustments are made to ensure that it is running correctly.

We design industrial dehydrators by first assessing the specific needs of the business, including the types of products to be dehydrated and any special requirements or constraints.

We then create a conceptual design and develop it into a detailed design, including specifying the dimensions and materials and selecting the appropriate drying technology.

Our design is then simulated and tested to ensure it will perform as expected.

The final design is then used to fabricate and assemble the dehydrator, which is then installed and commissioned at the customer’s facility and any necessary adjustments are made to ensure its proper operation.

At Enertherm Engineering, we understand that the support and installation of your industrial dehydrator is just as important as the design and manufacturing process. That’s why we offer comprehensive support and installation services to ensure that your dehydrator is running at its best.

Our team of experienced technicians will work closely with you to ensure a smooth and efficient installation process. We will also provide training for your staff to ensure that they are able to operate and maintain the dehydrator properly.

Once your dehydrator is up and running, our team will be on hand to provide ongoing support and maintenance. We offer regular check-ups and service agreements to ensure that your dehydrator is always running at its best. In the unlikely event that you experience any issues with your dehydrator, our team will be on hand to provide prompt and effective solutions.

We also offer remote monitoring services, which allows us to keep an eye on your dehydrator’s performance and alert you to any potential issues before they become a problem. This allows us to quickly identify and resolve any issues, minimizing downtime and ensuring that your dehydrator is always running at peak performance.

So, whether you need assistance with the installation of your new dehydrator or ongoing support and maintenance, you can count on Enertherm Engineering to provide the expertise and service you need.

Contact us today to hear more!

Our team is dedicated to providing the best possible customer service and support, so don’t hesitate to reach out if you have any questions or concerns.