HEFEI, CHINA – A colossal 400-tonne toroidal field magnet coil box, hailed as the world’s largest of its kind, has been successfully delivered to the Comprehensive Research Facility for Fusion Technology in Hefei, China. This monumental component, measuring 21 meters by 12 meters, marks a significant stride in the development of advanced fusion energy systems, demonstrating cutting-edge manufacturing capabilities in the pursuit of clean, limitless power.

The delivery underscores the rapid progress in fusion research and engineering globally, as nations push the boundaries of technology to harness the same power that fuels the sun and stars. While not explicitly part of the International Thermonuclear Experimental Reactor (ITER) project, this component’s scale and function rival or exceed similar parts within that multinational collaboration, highlighting a parallel advancement in fusion technology.

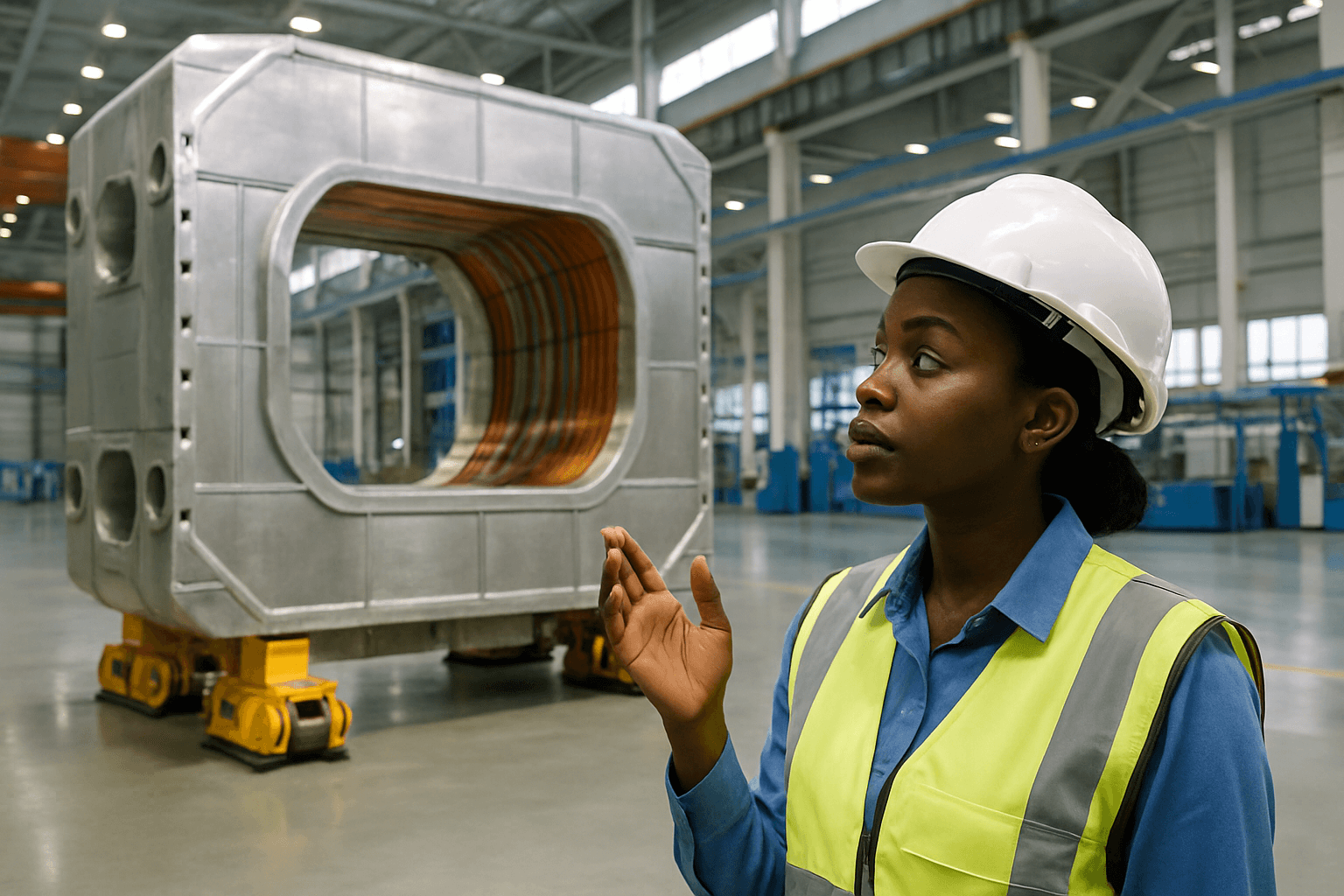

The Significance of the Toroidal Field Coil Box

This immense coil box serves as a critical structural element for toroidal field magnets within a fusion device. Its primary role is to protect the toroidal field coil windings and provide crucial support and securement for other superconducting magnets, including the poloidal field magnets. Constructed from ultra-low-temperature austenitic steel, its sheer size and weight (400 tonnes) signify the extreme forces it is designed to withstand during fusion reactor operation.

Experts at Shanghai Electric, the manufacturer, stated that this coil box is more than 1.2 times the size and approximately double the weight of similar components used in the ITER fusion project in France. Its successful delivery to the Hefei facility is a testament to years of dedicated research, overcoming numerous technical hurdles in its design and fabrication.

Overcoming Manufacturing Challenges

The production of such a massive and intricate component presented formidable engineering challenges. The project team spent five years innovating and refining manufacturing processes. Key advancements included the development of specialized welding techniques, combining high-thickness laser welding with ultra-deep narrow-gap tungsten inert gas welding, to handle materials with a maximum thickness of 360mm.

Furthermore, precision forming technology was devised for 30-meter-long spatial bends, alongside methods for cooling tube fixation using low-temperature resin and brazing. These innovations ensured high-precision installation of the critical cooling tubes, which are essential for the superconducting magnets to operate efficiently at cryogenic temperatures.

The Role of Magnets in Fusion Energy

Fusion energy aims to replicate the process within stars, where light atomic nuclei fuse to release enormous amounts of energy. To achieve this on Earth, powerful magnetic fields are used to confine a superheated plasma, preventing it from touching the reactor walls. Devices known as tokamaks, which have a doughnut-shaped vacuum chamber, are the leading design for magnetic confinement fusion reactors.

Within a tokamak, several types of magnets work in concert:

- Central Solenoid: Often called the “heart” of the tokamak, it induces the majority of the magnetic flux change needed to initiate and maintain the plasma current. The ITER Central Solenoid, built by the United States, stands 18 meters tall, weighs 1,000 tons, and can generate magnetic fields powerful enough to lift an aircraft carrier. Its six individual modules, each weighing over 122,500 kg (270,000 pounds), have recently been completed and delivered to France.

- Toroidal Field (TF) Coils: These D-shaped magnets are positioned around the vacuum vessel to create a strong toroidal magnetic field, confining the plasma in a “magnetic cage.” ITER will use 18 such coils.

- Poloidal Field (PF) Coils: These ring-shaped magnets, placed horizontally, help shape the plasma and keep it stable, suspended away from the chamber walls.

All these superconducting magnets must operate at extremely low temperatures, near absolute zero (around 4.5 Kelvin), requiring sophisticated cryogenic systems to maintain their zero electrical resistance and ensure efficient power consumption.

Broader Impact on Fusion Development

The successful delivery of this world’s largest toroidal field coil box not only advances China’s domestic fusion research program but also significantly contributes to the global knowledge base for high-end fusion equipment manufacturing. The technologies developed for this component—such as advanced welding, precision forming, and low-temperature material fixation—have potential applications beyond fusion, including aerospace, energy equipment, shipbuilding, and offshore engineering.

The global fusion energy landscape is marked by several large-scale collaborations and projects, with ITER being the most prominent. ITER is a multinational megaproject in southern France involving 30 nations, including China, the European Union, India, Japan, South Korea, Russia, and the United States. Its goal is to demonstrate the scientific and technological feasibility of fusion power at a commercial scale, aiming for a tenfold energy gain (500 MW of power output from 50 MW of input).

While ITER continues its assembly phase, with revised timelines now targeting initial operations with deuterium-deuterium fusion in 2035 and full deuterium-tritium fusion power by 2039, milestones like the delivery of this massive coil box in China signify the distributed yet collective progress towards a fusion-powered future. These advancements are crucial steps on “the way” (iter in Latin) to realizing fusion as a sustainable, carbon-free energy source for the world.