×About This Calculator

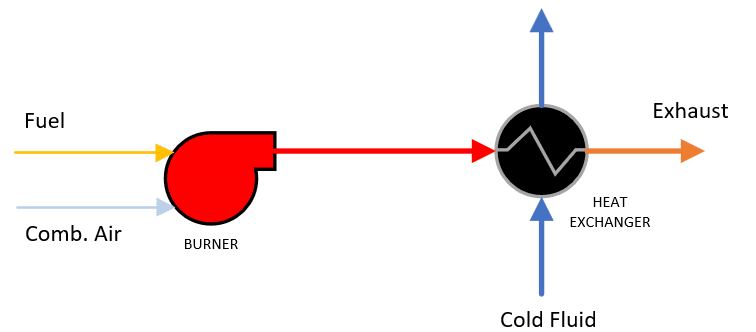

This interactive tool is designed to showcase the impact of burner performance on energy efficiency, fuel cost, and CO₂ emissions in a combustion heating system. It's a simple, effective way to explore how tuning burner parameters can lead to measurable operational savings.

Whether you're working with water, air, or edible oil as the process fluid, this calculator demonstrates the benefits of optimizing your burner and heat exchanger setup through a clear, scenario-based comparison.

What It Does

1. Define Your Scenarios

Model two operating conditions (Scenario A and Scenario B) using fuels like Natural Gas or Diesel. The system simulates how combustion gases heat a cold fluid via a heat exchanger.

You control key burner parameters:

- Combustion air temperature

- Excess air level

- Burner efficiency

- Exhaust temperature (after the heat exchanger)

To ensure a fair comparison, all cold-side fluid conditions are kept constant between the two scenarios.

2. See the Energy Impact

The tool performs a heat and mass balance to calculate:

- The thermal duty the burner must deliver

- The fuel mass flow required in each case

3. Discover Cost & CO₂ Savings

With a few simple inputs (fuel price and operating hours) you’ll get:

- Estimated annual fuel costs

- Cost savings between scenarios

- CO₂ emissions reduction in improved combustion efficiency