Crisp Production Optimisation – Operation Crispy Crisp Case Study

EnerTherm Engineering Ltd saves energy and waste in the food and processing industries. One of their customers operates a very large crisp production. These large production lines are capable of delivering 3.2 tons per hour of crisps, which is about 1 million bags of crisps per day.

Crisp moisture is one of the critical KPIs. The crisp moisture must be in spec for the product to be bagged, if the level is either too wet or too dry it will affect not only the shelf life but also the taste and texture.

We worked with a crisp production site to reduce waste from 700kg to 30kg for each production run and save 180 cubic metres of gas emissions. Overall savings for this project equated to £10K per line.

Our customer presented a problem during the line start-up which was creating a large amount of waste (700kg) due to moisture levels not being in spec.

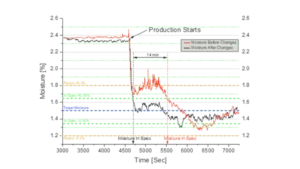

EnerTherm Engineering created an optimisation method based on data captured during the line start-up. Process control algorithms were changed to improve line responsiveness.

A number of control loops were also tuned over a 4-day period to reduce the time to bring the line back into control and reduce the start-up time by 14 min.

Result: Waste was reduced to 30kg. In addition, 180 m3 of gas was saved during the line start-up. Production lines will typically carry around 10-20 start-ups a week.

Enertherm Engineering focus on solving production-related issues and fixing non-optimal plant operation, where reducing energy waste is at the heart of the customer’s focus.