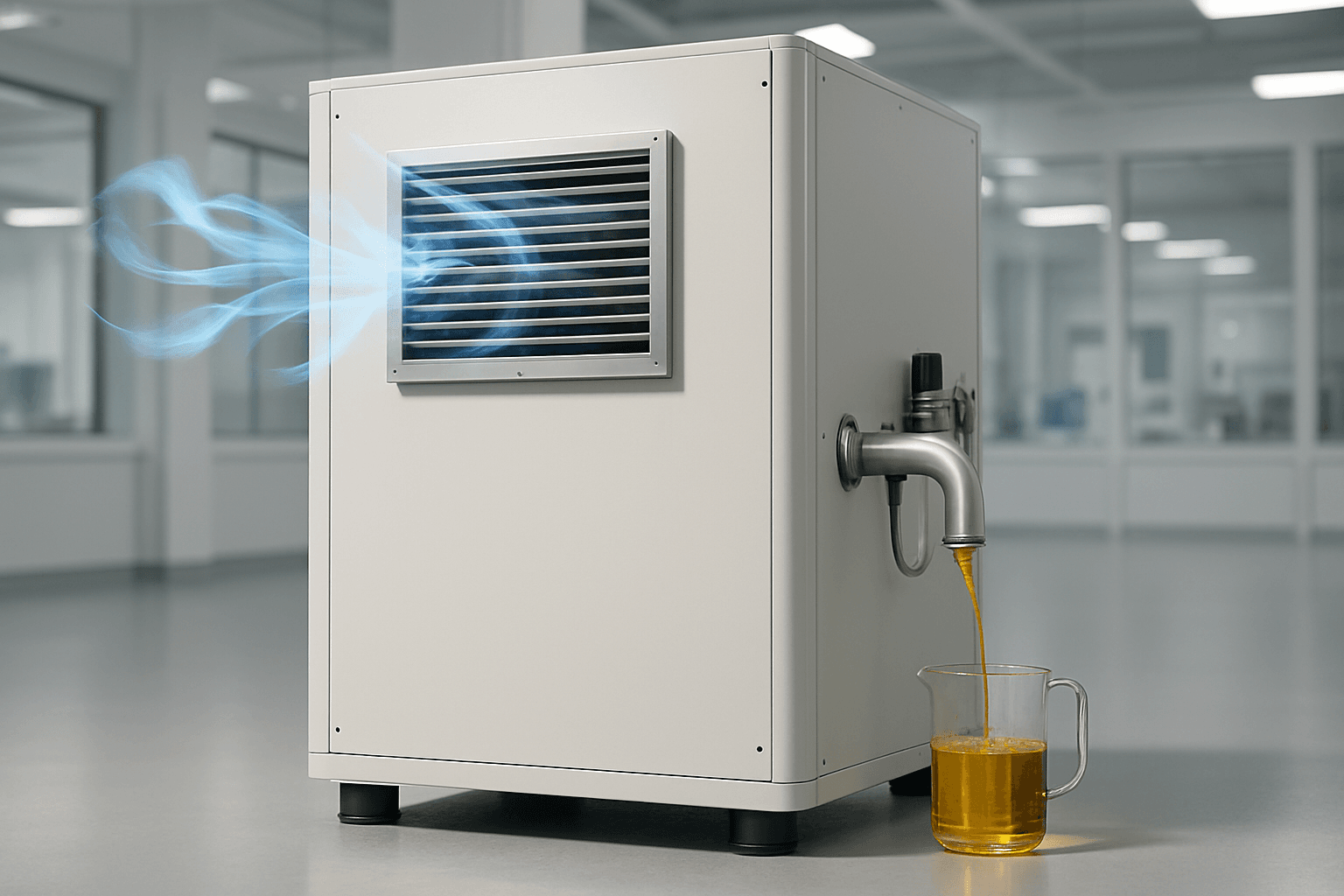

Imagine a world where gasoline isn’t extracted from the earth but created from the very air we breathe. A groundbreaking technology is making this a reality, offering a promising path toward a sustainable future. A New York-based company, Aircela, has recently unveiled the first working machine in the U.S. that produces gasoline directly from air. This innovative device, about the size of a refrigerator, could revolutionize the way we produce and consume fuel.

What is this Machine?

The Aircela machine is a compact, modular unit that combines direct air capture (DAC) and on-site fuel synthesis. It pulls carbon dioxide (CO2) directly from the atmosphere and converts it into gasoline that is fully compatible with today’s engines, requiring no modifications. This approach differs significantly from large-scale synthetic fuel projects, offering a fully modular, instantly deployable solution built for distributed production.

How Does it Work?

The machine uses a process that involves several key steps:

- Direct Air Capture (DAC): The machine captures CO2 directly from the ambient air. This process uses special filter materials or liquids that selectively bind to CO2. Once the material is loaded with CO2, it is released and recovered in pure form.

- Hydrogen Production: Hydrogen is a vital component in synthesizing e-fuels. It is produced through electrolysis, a process that splits water into hydrogen and oxygen using renewable energy sources like wind or solar power.

- Fuel Synthesis: The captured CO2 is combined with hydrogen in a synthesis process, such as Fischer-Tropsch synthesis or methanol synthesis, to produce a range of hydrocarbons. These synthetic fuels, including methanol, gasoline, and diesel, mimic traditional fuels but with a significantly lower carbon footprint.

Key Components and Processes

- Carbon Capture: Capturing CO2 from industrial emissions or directly from the atmosphere.

- Hydrogen Production: Using electrolysis powered by renewable energy to split water into hydrogen and oxygen.

- Fischer-Tropsch Synthesis: Combining CO2 with hydrogen to produce hydrocarbons.

The Promise of E-Fuels

E-fuels, or synthetic fuels, represent a promising avenue for sustainable energy. They are produced using renewable energy and can drastically reduce the harmful emissions associated with combustion engines. E-fuels are climate neutral and can be used to power vehicles, airplanes, and ships.

Benefits of E-Fuels

- Carbon Neutrality: E-fuels offer a carbon-neutral alternative to fossil fuels, supporting decarbonization in sectors like transportation and aviation.

- Compatibility: E-fuels are compatible with existing infrastructure and engines, making them a practical solution for reducing greenhouse gas emissions.

- Renewable Energy Integration: E-fuels integrate renewable energy and innovative chemical processes, playing a pivotal role in achieving global carbon neutrality goals.

- Lower Emissions: E-fuels drastically reduce harmful emissions associated with combustion engines.

- Versatility: E-fuels can be used to power vehicles, airplanes, and ships.

The Production Process of E-Fuels

The production of e-fuels involves several steps:

- Green Hydrogen Production: Green hydrogen is produced through electrolysis, splitting water into hydrogen and oxygen using renewable electricity.

- Carbon Capture: CO2 is captured from a point source, such as a smokestack, or directly from the air.

- Synthesis: Hydrogen binds with CO2 under high pressure using a catalyst to produce synthetic methanol.

- Fischer-Tropsch Synthesis: A condensation polymerization reaction of CO produces hydrocarbons, olefins, paraffins, and oxygenates.

Aircela’s Innovative Approach

Aircela’s approach to producing gasoline from air is unique in several ways:

Modular and Deployable

Unlike large-scale synthetic fuel projects, Aircela’s machines are fully modular and instantly deployable. This allows for distributed production, making it easier to set up fuel production in various locations.

Compatibility

The gasoline produced by Aircela’s machines is fully compatible with today’s engines, requiring no modifications. This is a significant advantage, as it eliminates the need for new vehicles or infrastructure.

Distributed Production

Aircela’s machines are built for distributed production, offering a climate-aligned alternative to fossil fuels without requiring new infrastructure or vehicles.

Strategic Investment

Aircela is backed by strategic investors like Maersk Growth, the venture arm of shipping company A.P. Moller – Maersk, who see Aircela’s technology as a meaningful step toward global decarbonization efforts.

The Science Behind CO2 Conversion

Converting CO2 into fuel involves advanced technologies and chemical processes. One promising technology involves Dual-Function Materials (DFMs), which combine carbon capture and conversion. This process could offer a more cost-effective way to remove CO2 from the air and turn it into clean, synthetic fuel.

Key Technologies

- Dual-Function Materials (DFMs): Combine carbon capture and conversion into a single process.

- Photoelectrochemical Cells: Use solar energy to convert CO2 into fuel.

- Metal Phthalocyanines: Low-cost pigments and metal complexes that act as catalysts in CO2 conversion.

Research and Development

Researchers at institutions like MIT and Harvard University have developed efficient processes to convert CO2 into formate, a liquid or solid material that can be used to power a fuel cell and generate electricity. Additionally, scientists at Tohoku University, Hokkaido University, and AZUL Energy, Inc. have created a method for converting CO2 into carbon monoxide (CO), an important building block for synthetic fuels, reducing the conversion time from 24 hours to just 15 minutes.

Challenges and Opportunities

While the technology to produce gasoline from air is promising, there are challenges to overcome:

Cost

The cost of producing e-fuels is currently higher than traditional fossil fuels. However, with advancements in technology and increased production, the cost is expected to decrease.

Energy Requirements

Producing hydrogen through electrolysis requires a significant amount of energy. To ensure the sustainability of e-fuels, it is essential to use renewable energy sources to power the electrolysis process.

Infrastructure

While e-fuels are compatible with existing infrastructure, there is a need to scale up the production and distribution of e-fuels to meet global demand.

Opportunities for Growth

Despite these challenges, there are significant opportunities for growth in the e-fuel sector:

- Investment: Increased investment in research and development can lead to more efficient and cost-effective e-fuel production technologies.

- Policy Support: Government policies that support the production and use of e-fuels can help to create a market for these sustainable fuels.

- Partnerships: Collaboration between industry, research institutions, and governments can accelerate the development and deployment of e-fuel technologies.

Real-World Applications

The potential applications of machines that produce gasoline from air are vast:

Transportation

E-fuels can be used to power cars, trucks, airplanes, and ships, reducing the carbon footprint of the transportation sector.

Aviation

The aviation industry is particularly interested in e-fuels as a way to decarbonize air travel. E-kerosene, a type of e-fuel, is emerging as a priority for the aviation sector.

Industrial Applications

E-fuels can replace fossil feedstocks in sectors like steel manufacturing, offering a sustainable path to decarbonize industries that are otherwise hard to electrify.

Distributed Energy Production

Modular machines that produce gasoline from air can be deployed in various locations, providing a decentralized source of fuel and reducing the need for long-distance transportation.

The Future of Fuel

The development of machines that produce gasoline from air represents a significant step toward a sustainable future. While there are challenges to overcome, the potential benefits of e-fuels are immense. As technology advances and production scales up, e-fuels could play a crucial role in reducing greenhouse gas emissions and mitigating climate change.

Companies Leading the Way

Several companies and organizations are leading the way in the development of e-fuel technologies:

- Aircela: A New York-based company that has unveiled the first working machine in the U.S. that produces gasoline directly from air.

- Climeworks: A Swiss company that is constructing direct air capture and CO2 underground storage plants.

- HIF Global: Planning large-scale power-to-liquids production facilities.

Final Thoughts

The fridge-sized machine that produces gasoline from air is more than just a technological marvel; it’s a beacon of hope for a cleaner, more sustainable future. As we continue to innovate and invest in e-fuel technologies, we can pave the way for a world where fuel is produced from the very air we breathe, reducing our reliance on fossil fuels and mitigating the impacts of climate change.