HEAT FLUX MAPS FOR OVENS: CONCEPT OF BAKING COMFORT ZONES

by

François Pierrel

Achieving rapid baking in industrial tunnel ovens, while maintaining adequate product quality is a significant challenge. The application of excessive heat fluxes to a low-diffusivity heterogeneous food product can easily yield a product of poor quality (colour, texture, flavour).

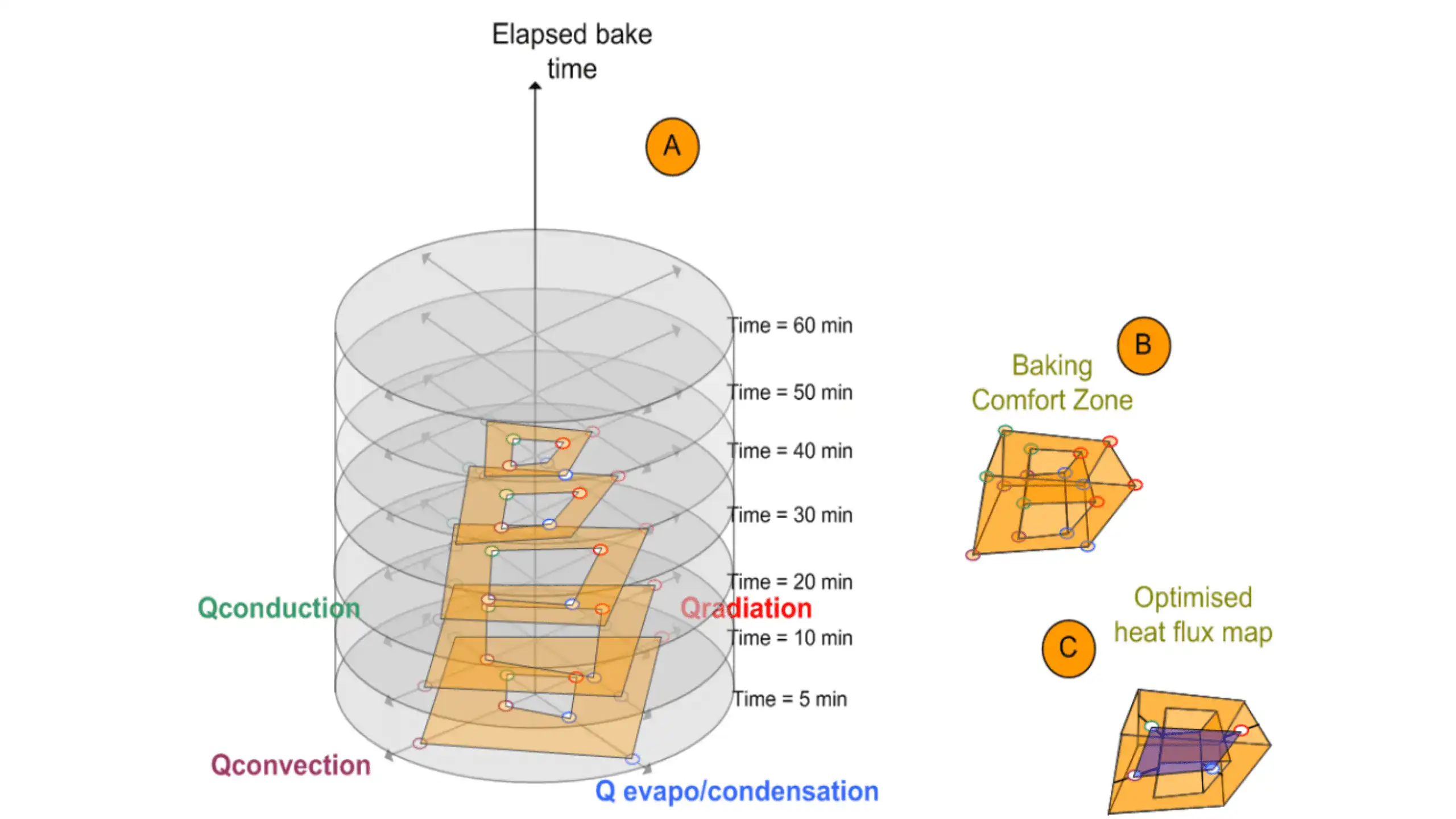

It is desirable to optimize the application of heat on a transient basis during the baking process in order to minimize bake times and achieve an acceptable set of product responses (e.g. colour, height, crust hardness, crumb moisture, weight loss). The magnitudes of the convective, radiative, condensing/evaporating and conductive heat fluxes dictate the quality of the baked product and the process efficiency.

By mapping the applied fluxes with time a “baking comfort zone” can be established. The map can be developed to indicate minima and maxima flux values and/or to identify an optimal heating profile. The baking comfort zone for a given product provides a useful visual indicator, which can be related to a similar indicator of product responses to improve understanding of the baking process. Furthermore, provided adequate instrumentation is available, the baking comfort zone can be utilized:

- By the operator of an oven at the process control interface to ensure that an appropriate heating profile is being achieved in practice.

- Also to replicate products in different ovens. This concept is based upon baking tests conducted on a high-performance research oven manufactured by APV Baker (UK) and installed in their research centre in Peterborough England.