Each year, vast quantities of potatoes are processed into widely consumed foods such as french fries and potato chips. However, within the byproducts of this production, particularly the peels, lies a considerable amount of starch that often goes unutilized. Consider the possibility that this processing residue could be transformed into a resource for sustainable food products, yield substantial financial benefits, and even be used in crafting high-quality alcoholic beverages.

This exploration looks into the significant, yet often underappreciated, practice of starch reclamation.

Unearthing Value from Potato Byproducts

A typical potato is composed of about 80% water and 20% solid matter, the majority of which is starch. During industrial processing, especially the peeling and slicing stages, a notable portion of this starch is either washed away or remains in the discarded peelings. The amount of waste generated can range from 6% to 10% of the potato’s initial weight, varying with the type of peeling equipment used.

Even advanced steam peeling techniques, prevalent in high-volume facilities, which produce less peel waste than traditional abrasive methods, still leave a significant opportunity for starch recovery.

To put this into perspective:

Analyzing a 4-Tonne Potato Batch – Potential Starch Yield:

- Peel Residue: This would amount to roughly 6–10% of the total, or 240–400 kg.

- Starch Proportion in Peel: Approximately half of the peel’s dry weight is starch.

- Peel Moisture Content: Fresh potato peels usually have a moisture level of around 80%.

- Peel Dry Solids: This indicates that about 20% of the peel residue consists of dry solids, totaling 48–80 kg.

- Estimated Recoverable Starch: With recovery processes achieving 60–80% efficiency, it’s feasible to retrieve 30–64 kg of starch from the peels of this batch.

Moreover, this estimate does not include the starch that becomes suspended in the water used during processing.

Starch Content in Process Water: A Frequently Ignored Resource?

According to industry analyses, an additional 1–2% of the total potato input weight can be lost as starch into the processing water when potatoes are cut or diced. For the 4-tonne batch example, this translates to an extra 40–80 kg of starch typically flushed away.

This loss represents not only inefficiency but also a considerable economic drain. The discharge of starch-laden water leads to increased expenses, as water treatment fees are often calculated based on Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD). The presence of starch significantly elevates these levels.

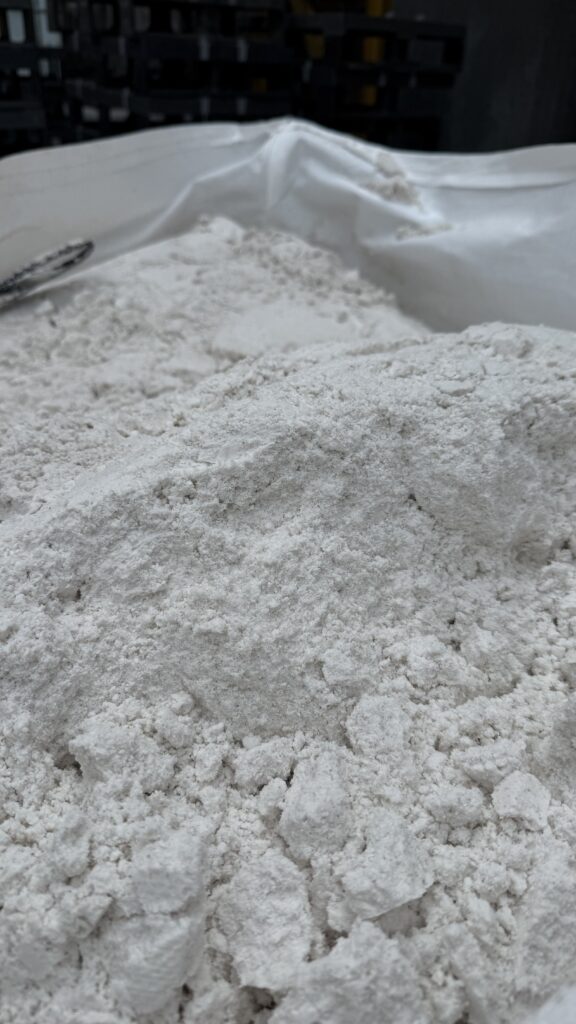

An effective technological solution is the use of decanter centrifuges. These advanced, high-velocity machines excel at separating starch from wastewater. Their implementation reduces effluent charges and converts a waste product into a valuable material with a moisture content below 40%. This is not a speculative technology but one already adopted by several innovative processing companies.

Diverse Uses for Reclaimed Starch

The potential applications for this recovered starch are remarkably varied:

- Culinary Sector: It can serve as a coating for potato chips and seasoned fries, or as a functional ingredient in novel snack foods.

- Alcohol Production: Distilleries have successfully employed recovered potato starch in the manufacturing of premium potato vodka. Some producers are known to supply their reclaimed starch to distilleries, effectively giving the potatoes a new purpose.

- Alternative Revenue Sources: The recovered starch can be marketed to starch refining companies.

- Eco-friendly Byproducts: It can be integrated into animal fodder or utilized in the creation of biodegradable plastics.

Advancing the Circular Economy

The practice of starch recovery extends beyond mere financial gain, although the economic advantages from reduced effluent costs and new product sales can be substantial. It is a clear example of the circular economy in action, contributing significantly to environmental stewardship through:

- Diminishing the volume of waste sent to landfills.

- Reducing the costs and environmental load associated with water treatment.

- Repurposing materials that have already entailed an environmental footprint in their initial production.

The Growing Significance of Starch Reclamation

As the food production sector increasingly prioritizes goals like zero-waste operations and carbon footprint reduction, starch recovery is shifting from a specialized activity to an essential industrial practice.

While the efficiency of recovery will differ based on individual plant configurations, deployed technologies, and specific operational methods, the fundamental opportunity is widespread. Whether a facility processes four tonnes or four hundred tonnes of potatoes daily, there is considerable untapped value in its wastewater and peelings.

Reflect on the positive outcomes of converting what was previously deemed waste into:

- Lowered expenses for water treatment

- Increased overall product output

- Avenues for creating new products

- Enhanced environmental performance and sustainability metrics

Conclusion: Realizing the Untapped Potential in Potato Processing

The reclamation of starch from potato byproducts like peels and process water presents a considerable opportunity for the food manufacturing industry. Beyond the direct financial benefits of decreased disposal expenses and the generation of marketable goods, this approach aligns with overarching industry objectives of efficient resource utilization and environmental responsibility. As food processors continually explore innovative methods to reduce waste and enhance value, the systematic recovery of starch emerges as a sensible and effective strategy. The necessary technologies are accessible, the advantages are evident, and the drive for adoption is accelerating. Implementing starch recovery is more than an operational enhancement; it is a strategic step toward a more sustainable and economically sound future for the potato processing industry.