Heat Recovery In Pet Food Odour Treatment Plant Case Study

A Pet Food Processing site had an issue with odour complaints from the local residents and we’re looking at a new odour treatment system across all the process lines.

EnerTherm Engineering investigated the use of incineration, combined with heat recovery, to access the suitability and viability of this method for the site.

The odour issue had been an ongoing problem, electrostatic precipitation and deodorising chemicals were trialled alongside the original absorption column but ultimately a new treatment system was needed to fix the problem. Incineration of the waste gases was one of the methods investigated. Incineration gives a very effective odour removal however was not used at this site.

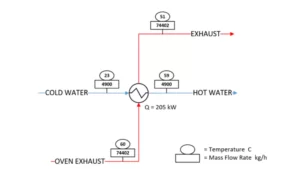

EnerTherm Engineering was given data from a previous site survey on the waste gas. From this information, the incinerator was sized and analysis was undertaken to maximise the heat recovery.

The combined foul gas flow rate was circa 300,000 m3/h, the gases need to be incinerated to 820 °C for 2 seconds to ensure full incineration.

This led to a large flow rate of natural gas required although this was minimised by preheating the waste gases and combustion air from the incineration exhaust. Even after this, there was scope to implement another heat exchanger to further recover heat for another process. The best payback came from recovering 500 kW of waste energy to 13,000 kg/h of hot water production.