Manufacturing environments often present inherent dangers, from exposure to toxic chemicals and extreme temperatures to the risks associated with heavy machinery and repetitive strain. These hazardous conditions not only endanger human workers but can also lead to decreased productivity, inconsistencies in quality, and significant operational costs. Advanced robotics offers a transformative solution, promising to mitigate these risks while simultaneously enhancing efficiency and precision. This article delves into the feasibility of deploying advanced robotics in such challenging industrial settings, exploring the myriad benefits, inherent complexities, critical considerations, and a strategic roadmap for successful integration.

The Transformative Benefits of Advanced Robotics in Hazardous Environments

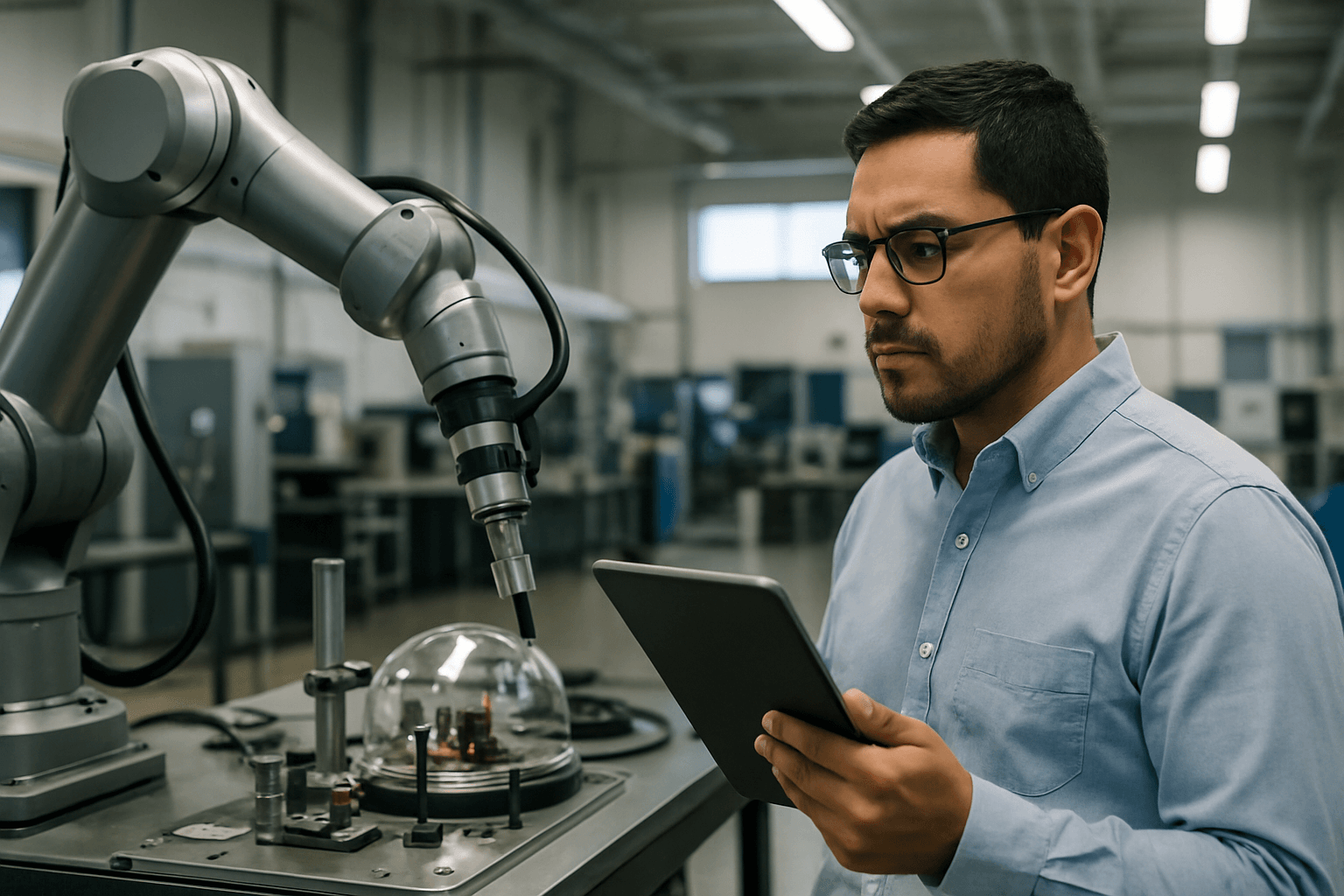

Implementing advanced robotic systems in hazardous manufacturing tasks yields a wide array of benefits, primarily centered on improving safety and operational performance.

Enhanced Worker Safety and Risk Reduction

The most compelling advantage of robotics in hazardous environments is the reduction or elimination of human exposure to danger. Robots can perform tasks in extreme heat, handle toxic materials, operate in confined spaces, or execute heavy lifting and repetitive motions, thereby significantly lowering the risk of accidents, injuries, and long-term health issues for human workers. This includes minimizing exposure to mechanical hazards, loud noise, high dust levels, and chemical exposure.

Increased Productivity and Efficiency

Automated robotic systems can operate continuously, often 24/7, without fatigue, breaks, or downtime, leading to substantially higher production rates and reduced cycle times. Their ability to maintain a constant pace and precision far outweighs human capabilities, particularly beneficial in high-demand and time-sensitive industries. This uninterrupted operation ensures consistent output regardless of shift changes or human error.

Improved Quality and Consistency

Robots are programmed to perform tasks with exact measurements and repeat them consistently, without variation. This precision is critical in industries where minor deviations can lead to product failures or safety hazards, such as aerospace or medical device manufacturing. The reduction in human error results in fewer defects, less scrap, and higher overall product quality, leading to cost savings and improved customer satisfaction.

Long-term Cost Savings and ROI

While the initial investment in robotics can be substantial, the long-term cost savings are significant. These include reduced labor costs in repetitive tasks, lower worker’s compensation claims due to fewer injuries, decreased waste material due to precision, and optimized energy consumption. Case studies have shown substantial ROIs, with some inspection robots paying for themselves in under eight months and achieving over 250% ROI in three years in chemical manufacturing.

Types of Advanced Robotics for Dangerous Tasks

Modern manufacturing utilizes various advanced robotic systems tailored for specific hazardous applications:

Industrial Robots

These are typically large, high-speed machines often deployed behind safety cages, performing tasks like welding, painting, drilling, grinding, and material handling in environments too dangerous for humans. Examples include articulated robots and SCARA-style robots used in automotive and other industries for precise operations in hazardous settings.

Collaborative Robots (Cobots)

Designed to work safely alongside humans, cobots are equipped with advanced sensors that detect human presence and can stop or adjust their speed to prevent injury. They are particularly useful for tasks requiring human-robot interaction, offering flexibility and ease of integration.

Autonomous Mobile Robots (AMRs)

AMRs use advanced navigation technology, including LIDAR, cameras, and GPS, to move autonomously through dynamic environments. They can transport materials, manage inventory, and monitor hazardous areas without human intervention, ideal for large facilities or complex layouts.

Specialized Robots

This category includes robots developed for highly specific hazardous tasks, such as:

- Hazardous Material Handling Robots: Designed to handle and neutralize toxic or combustible substances remotely, equipped with advanced sensors for real-time data.

- Inspection and Maintenance Robots: Drones, quadruped robots, and underwater robots equipped with sonar and AI for inspecting pipelines, boilers, nuclear power plants, and other inaccessible or dangerous infrastructure.

- Disaster Recovery Robots: A “golf bag” of robots, including drones and robot dogs, can gather information, collect samples, and even apply decontamination sprays in chemical, biological, radiological, and nuclear (CBRN) threat environments, replacing human intervention in highly dangerous situations.

Key Challenges and Considerations for Robotic Implementation

While the benefits are clear, several challenges must be addressed to ensure successful implementation of advanced robotics in hazardous manufacturing:

High Initial Investment and ROI Justification

Industrial robots require a significant upfront investment in equipment, installation, and configuration. Companies must conduct thorough ROI analyses, considering long-term savings from increased productivity, reduced waste, and enhanced safety to justify the capital expenditure.

Technical Complexity and Integration

Setting up and maintaining smart robotics systems demands a high level of technical expertise. This includes complexity in systems integration, data management, network security, and potentially integrating with existing legacy systems. Improper installation or programming can also introduce new hazards.

Workforce Adaptation and Skill Gaps

The introduction of robots necessitates a shift in workforce skills. While robots take over “dirty, dull, and dangerous” tasks, human workers need to be retrained for higher-skilled roles such as robot operation, programming, maintenance, and data analysis. Overcoming initial worker caution and ensuring comprehensive training are crucial for acceptance and effective human-robot collaboration.

Ensuring Robot Safety and Cybersecurity

Despite their safety benefits for humans, robots themselves can introduce hazards like unexpected movements, mechanical failures, electrical hazards, and control errors. Robust safety protocols, including physical barriers, sensors, emergency stops, and proper risk assessments, are paramount. Cybersecurity also becomes a concern, as integrated systems can be vulnerable to threats.

Regulatory Compliance and Standards

Adherence to industrial robot safety standards is critical. Key frameworks include ISO 10218 (for industrial robots), ISO/TS 15066 (for collaborative robots), and regional regulations like OSHA and ANSI/RIA R15.06. These standards define requirements for robot design, risk assessment, safety functions, and the use of safeguards such as emergency stops and speed limits.

Conducting a Feasibility Study: A Strategic Roadmap

A comprehensive feasibility study is essential before committing to robotic implementation in hazardous manufacturing.

1. Detailed Process Analysis and Hazard Identification

Begin with a thorough analysis of current manufacturing processes to pinpoint hazardous tasks, bottlenecks, and areas with high rates of human error or injury. Identify specific hazards (e.g., chemical exposure, extreme temperatures, repetitive strain, heavy lifting) and the underlying causes.

2. Technology Evaluation and Selection

Research and evaluate various advanced robotic systems suitable for the identified hazardous tasks. Consider factors such as robot type (industrial, cobot, AMR), payload capacity, reach, precision, speed, and environmental resilience (e.g., ability to operate in corrosive or high-temperature environments). Explore advanced features like AI, machine vision, and remote operation capabilities.

3. Comprehensive Risk Assessment

Conduct a detailed risk assessment in accordance with standards like ISO 12100, ISO 10218, and ANSI/RIA R15.06. This should identify potential hazards introduced by the robots themselves, assess human-robot interaction risks, and define necessary safeguarding measures (e.g., light curtains, safety interlocks, emergency stops, physical barriers).

4. Financial Analysis and ROI Projections

Develop a robust financial model that includes initial acquisition costs, installation, integration, programming, training, and ongoing maintenance. Project the anticipated savings from reduced injuries, improved productivity, waste reduction, and increased quality. Calculate the Return on Investment (ROI) and payback period to ensure financial viability.

5. Infrastructure and Facility Assessment

Evaluate the existing infrastructure to determine if modifications are needed for power, network connectivity, floor space, and environmental controls to support robotic systems. Consider the physical layout and any obstacles for mobile robots.

6. Workforce Planning and Training Strategy

Develop a strategy for workforce transition, including identifying new skill requirements, establishing comprehensive training programs for robot operators and maintenance personnel, and addressing potential concerns about job displacement.

7. Pilot Program and Scalability Assessment

Consider starting with a pilot program for a specific hazardous task to test the chosen robotic solution in a real-world scenario before full-scale deployment. Assess the scalability of the solution for future expansion and integration across the manufacturing facility.

Case Studies and Real-World Applications

Numerous industries have successfully implemented advanced robotics for hazardous tasks:

- Chemical Manufacturing: Robots handle toxic substances and operate in extreme temperatures, with some facilities reporting over 190% ROI and significant uptime increases.

- Automotive Production: Robots perform welding, painting, and assembly, reducing human exposure to fumes, repetitive motions, and heavy components.

- Steel Mills and Forging: Robots are used in high-temperature environments, reducing musculoskeletal disorder (MSD) risk factors and improving productivity.

- Nuclear Facilities: Advanced servomanipulators and specialized robots are employed for remote operations, inspection, and decontamination in radioactive environments.

- Mining and Disaster Recovery: Quadruped robots navigate dangerous or unstructured terrain for inspection and safety patrols, reducing human entry into hazardous zones.

The Future Outlook for Robotics in Hazardous Manufacturing

The landscape of advanced robotics in manufacturing is continuously evolving. Future trends point towards even more sophisticated human-robot collaboration, where robots become more intelligent, adaptive, and capable of complex decision-making through AI and machine learning integration. Technologies like the industrial metaverse will allow virtual design and testing of production lines, further streamlining implementation. As robotics technology advances, its accessibility and cost-effectiveness are expected to improve, making it viable for a broader range of manufacturers, including small and medium-sized enterprises (SMEs). The focus will remain on building “mutual trust” between robots and humans, bridging AI with mechanical necessities to enhance robot awareness and intelligence.

Conclusion

The feasibility of implementing advanced robotics for hazardous manufacturing tasks is not merely a theoretical concept but a proven reality, driven by undeniable benefits in safety, productivity, quality, and long-term cost savings. While significant challenges related to initial investment, technical complexity, workforce adaptation, and stringent safety regulations exist, a methodical and strategic approach to feasibility studies, coupled with adherence to international standards, can effectively mitigate these hurdles. As technology continues to advance, advanced robotics will increasingly serve as an indispensable tool, transforming dangerous industrial landscapes into safer, more efficient, and more productive environments for the benefit of both industry and humanity.