[ivory-search id="47677" title="mobile menu search"]

- Industrial Energy Audit

- Pinch Analysis

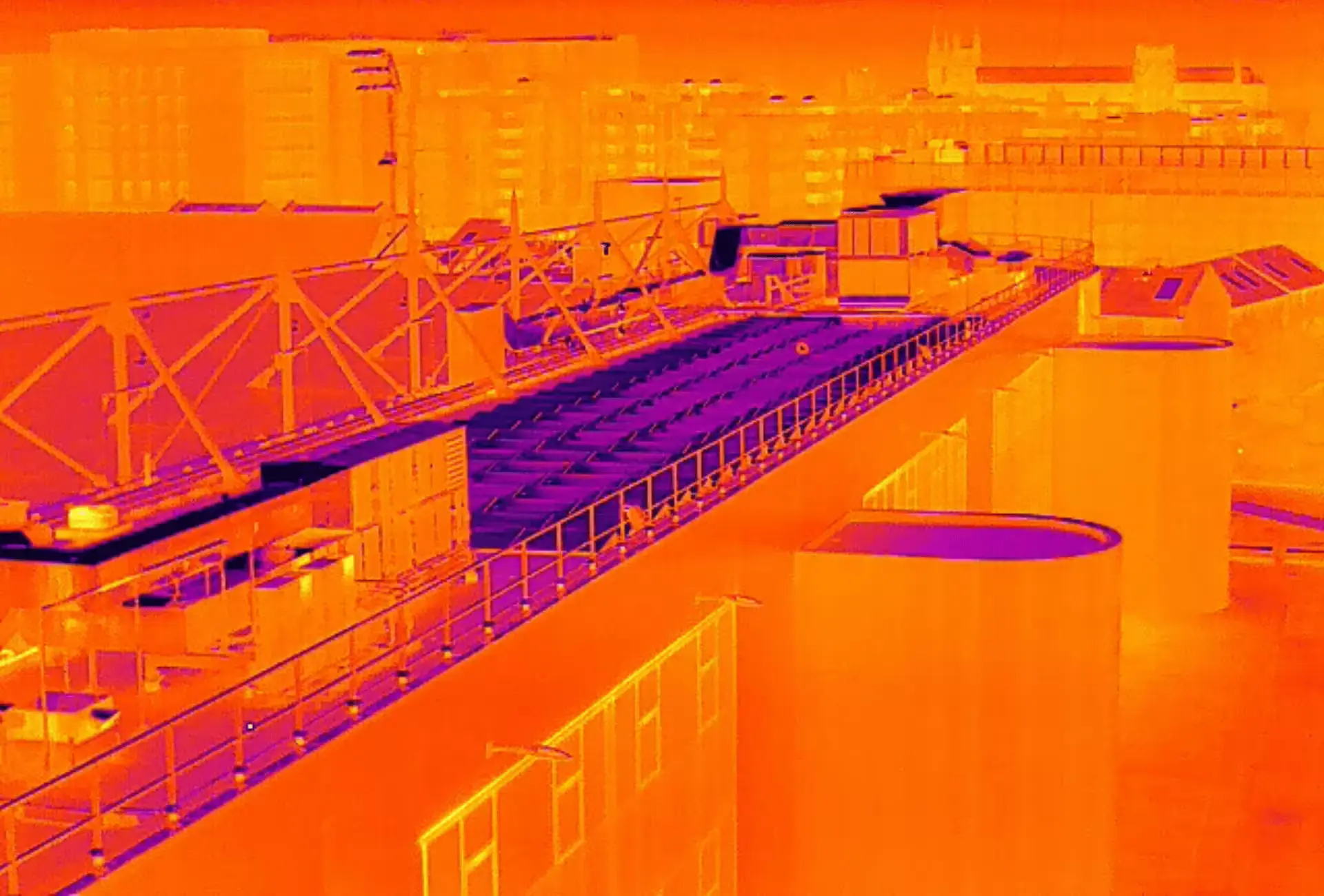

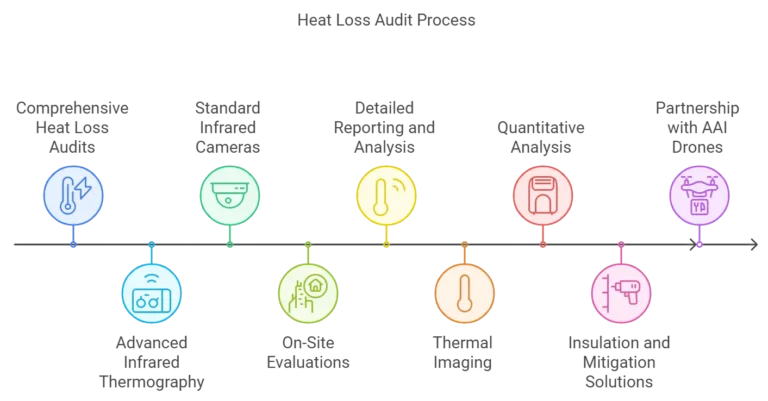

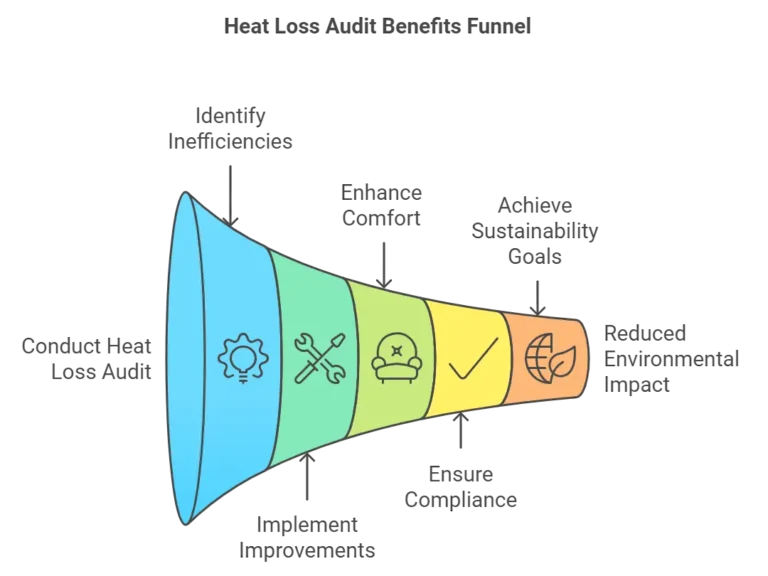

- Heat Loss Audit

- Design of Process Equipment

- Heat and Mass Balance

- Thermal Design Simulation

- Process and Production Optimisation

- Industrial Process Modelling

- Process Evaluation

- Design of Experiment (DoE)

- Design Prototyping

- Feasibility Studies

- Industrial Engineering Project Management

- Industrial Software Development

Show All

-

Enertherm Engineering,

Allia Future Business Centre, London Rd,

Peterborough PE2 8AN - +44 (0) 7949 863 273

- +44 (0) 1733 666 701

- info@enertherm-engineering.com

-

EnerTherm-Engineering.com 2024.

All rights reserved.