Process Integration And Pinch Analysis Case Study

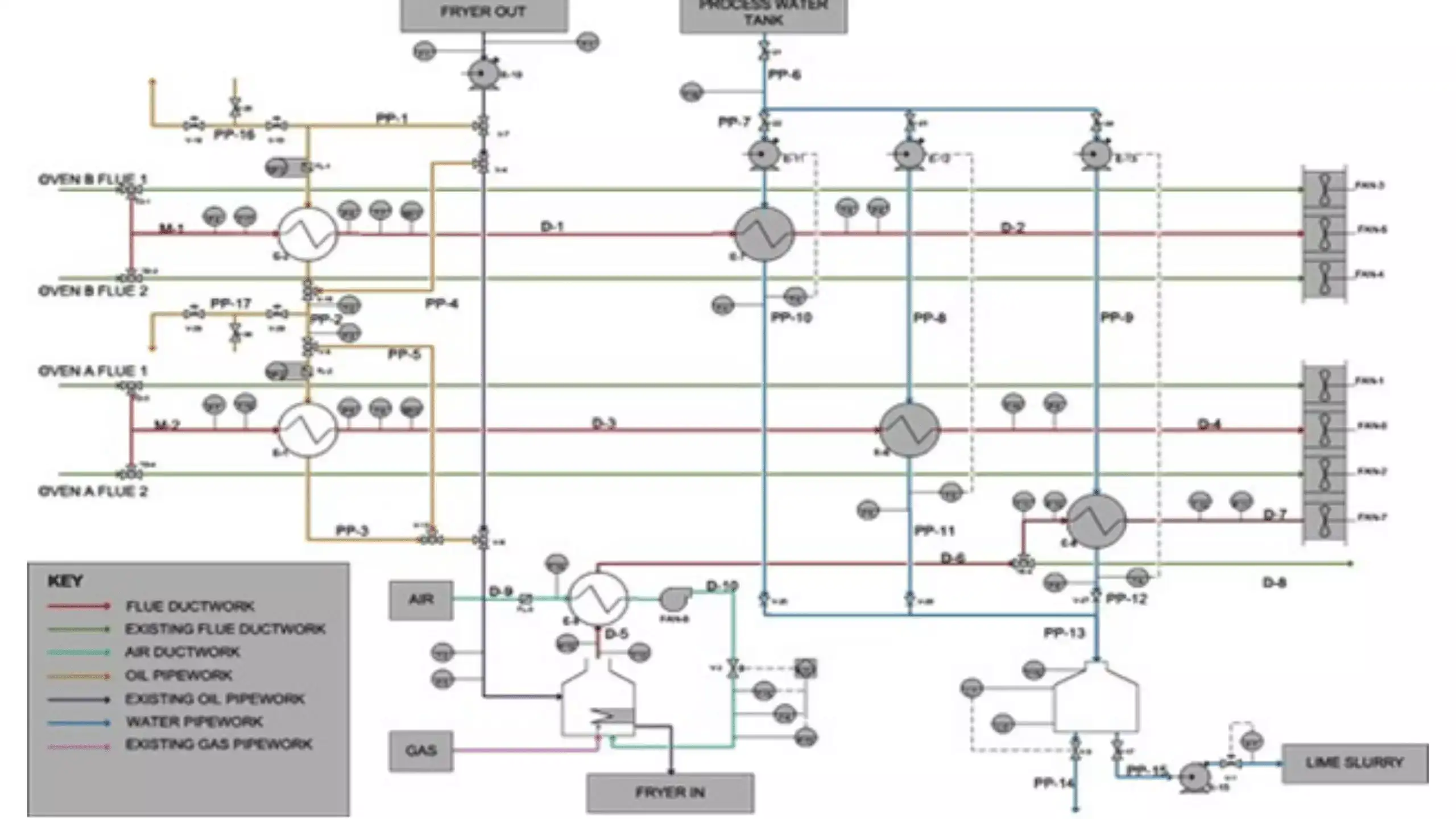

A Blue-chip Food Company reached out to EnerTherm Engineering to perform a Pinch Analysis of all processing lines on one of their sites. They needed to assess their energy usage and find possible areas for heat recovery or energy usage reduction.

Pinch analysis is a method for optimising and maximising heat recovery systems across industrial processes and therefore minimising energy consumption.

The information needed for the analysis was queried from site databases were available with onsite measurements used to find outstanding information. This allowed the site’s hot and cold streams to be mapped, with minimum hot and cold utility requirements found and multiple heat exchange networks modelled.

The design with the best performance gave a payback of 2.7 years, with gas and steam savings of 790 kW equating to circa £125,000/pa savings.

Pinch analysis is a method for optimising and maximising heat recovery systems across industrial processes and therefore minimising energy consumption.