Precious Metal Incinerator Case Study

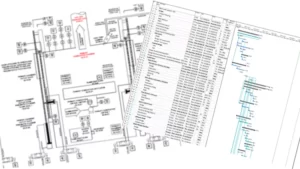

EnerTherm Engineering Ltd has designed a unique batch incinerator for a famous Jewellery watch manufacturer. This bespoke design encompasses a feed-in-out system bar scanned for all trays of waste to be incinerated. A dual chamber incineration system in conjunction with sorbent treatment allows minimum emission which complies with strict OPAIR regulations.

Bespoke filtration and mixing system have allowed reducing dust emission significantly. A complete heat recovery bypass heat exchanger system allows optimum production of hot water for the site during the winter and summer periods. The overall process allows recovering the equivalent of £45k of gold monthly.

Working in conjunction with our customer, we have managed the design and execution of a bespoke batch solid waste incinerator for the precious metal, recovering the equivalent of £45K gold per month.

The multi-batch incinerator has been designed to deal with several typologies of waste from the customer. A recipe system also supervised by an IR camera handles the various types of waste to ensure complete incineration. The control system reacts to each waste independently adjusting the sorbent flow rate to ensure complete neutralization of acid.

A large amount of process / CFD simulation had to be carried out through the design phase to check key design parameters that would allow delivering throughput, and key emission parameters (residence time of solid particles..)

EnerTherm Engineering has also developed a bespoke reporting system linked to the customer SAP system, which provides daily / weekly monthly required process information to ensure emissions are within the tolerated range.

EnerTherm Engineering delivered a unique solution to this customer in a dual-language environment. Managing both the design and multiple fleets of sub-contractors, whilst managing the customer expectation and budget constraints.

EnerTherm Engineering excels in this environment and has managed to develop over the years some multi-design skills to allow for managing such a bespoke and elaborate project.