Thermal Shield For Nuclear Plant Case Study

EnerTherm Engineering Ltd has designed two thermal shields for nuclear waste oven treatments for the Sellafield plant in England.

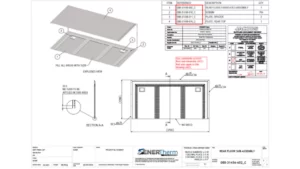

Both ovens are sitting on the factory floor in an area which is made of epoxy flooring coating. Working directly with Jacobs Engineering, our engineers have designed two unique thermal shields to protect the floor from excessive heat and prevent it from cracking. The shields also ensure no changes to the performance of the oven in this highly secure environment. As well as being highly thermal insulating, the shields needed to support the entire oven weight keeping it level.

The Thermal Shields produced by EnerTherm Engineering has been designed to be structurally sound and thermally insulating to support the oven weight and insulate the epoxy-based flooring.

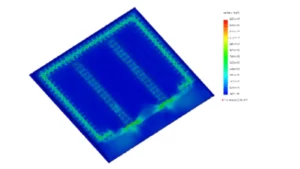

Designing two unique thermal shields for Jacobs Engineering for Sellafield nuclear waste oven treatment, EnerTherm Engineering had to work under strict mechanical and thermal constraints. They used FEA stress and thermal analysis to design and optimised the thermal shields.

The design allowed to distribute evenly the weight of the oven sitting on the shield but also minimise any hot spots and heat paths which would damage the epoxy floor. A high insulating spray coating was used all around the base of the oven thermal shield as well as 800 low insulative cylindrical billets with high tensile strength.

The thermal shield was demonstrated to have an excellent thermal resistance and remain structurally sound during repetitive loading and unloading of the waste in the oven.

EnerTherm Engineering has also developed a bespoke reporting system linked to the customer SAP system, which provides daily / weekly monthly required process information to ensure emissions are within the tolerated range.

EnerTherm Engineering delivered a unique and bespoke solution to Jacobs Engineering. Managing both the design, manufacturing and shipping of the thermal shield to Sellafield.

EnerTherm Engineering excels in this environment and has managed to develop over the years some multi-design skills to allow managing such a bespoke and elaborate project.